3D printing and its application

Digital & Technology

403 week ago — 4 min read

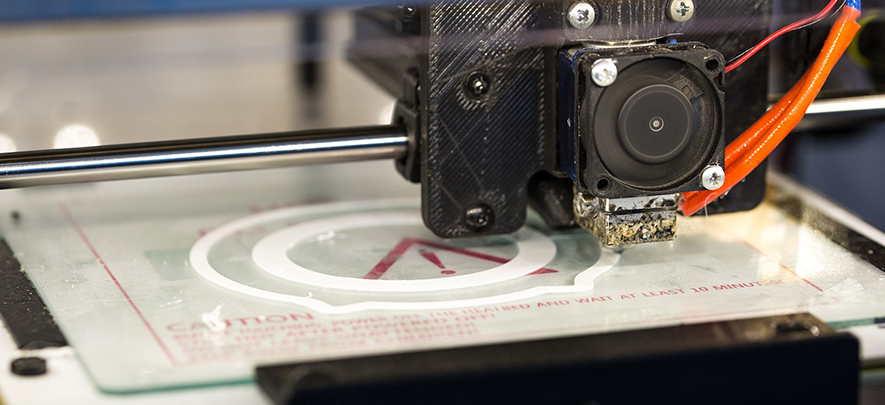

3D printing, also called Additive Manufacturing, refers broadly to techniques used to create 3D objects. The ‘printer’ applies materials in layers under the guidance of a computer to create the desired object.

There is no constraint to what shape the figure printed needs to be and as 3D printing evolves, size is also a barrier that is being steadily overcome. 3D printing allows the user to produce complex shapes using less material than in traditional methods of products. What is essential, in all forms of 3D printing, is to start with a computer model.

The process can be broken down into four stages - modelling, slicing, printing and finishing.

a. Modelling - Additive manufacturing takes virtual blueprints from computer aided design (CAD) or animation modelling software and "slices" them into digital cross-sections for the machine to successively use as a guideline for printing.

b. Slicing - Slicing software is used to slice 3D CAD.stl file and converts into G code which contains various printing parameter setting necessary for printing.

c. Printing - To perform a print, the machine reads the design and lays down successive layers of liquid, powder, or sheet material to build the model from a series of cross sections. These layers, which correspond to the virtual cross sections from the CAD model, are joined together or automatically fused to create the final shape. The primary advantage of this technique is its ability to create almost any shape or geometric feature. Six materials so far can be used in 3D printing - polymers, metals, concrete, ceramics, paper and certain edibles like chocolate.

d. Finishing - Though the printer-produced resolution is sufficient for many applications, printing a slightly oversized version of the desired object in standard resolution, and then removing material with a higher-resolution subtractive process can achieve a higher-resolution.

Applications of 3D printing are varied - it can be used to prototype, create medical devices and tools, in orthodontics, consumer goods and packaging, architecture, construction, art and fashion, aerospace and defence, electronics, jewellery, toys and in facilitating education.

As 3D printing technology advances, it will have more and more applications to our everyday world. Also, creating a prototype with 3D printing can be an extremely useful exercise in conserving resources for a company. It could be more economical than building a prototype the traditional way.

3D printing is becoming more and more prevalent and it will gradually become a part of the mainstream. In future, 3D printing will put the consumer in charge of what product he wishes to create. The nature of manufacturing will change with consumers able to envision and print a product without the need of going to the market to look for suitable goods that have been manufactured by corporations. Additionally medicine, art, construction and sciences will see their workings transformed with 3D printing. Worldwide, the 3D printing industry is expected to grow from USD 3.07 billion in revenue in 2013 to USD 21 billion by 2020.

Explore how 3D printing could benefit your industry. Odds are, there will be direct application of this transformative technology to the way you do business.

To explore business opportunities, link with me by clicking on the 'Invite' button on my eBiz Card.

Network with SMEs mentioned in this article

View Vishal 's profile

SME Inspirations

Other articles written by Vishal Jariwala

Importance of 3D printing in education

376 week ago

Most read this week

Comments (1)

Share this content

Please login or Register to join the discussion